- Home

- Damping Technology

- Friction Springs

Key Characteristics of the Friction Springs

RINGFEDER® Friction Springs are composed of meticulously crafted outer and inner rings, assembled into complete spring columns tailored to the user's specific requirements. Each spring undergoes rigorous testing and multiple load cycles before delivery, ensuring absolute functional reliability. It also known as "lò xo ma sát".

RINGFEDER® Friction Springs offer several advantages over conventional damping solutions:

- High spring work at low weight and volume: Optimal use of spring material reduces dimensions and weight.

- High damping capability: Standard damping at 66% quickly absorbs energy and suppresses resonance. Damping variations (33%-66%) are possible with specific lubricants.

- Performance independent of load speed: Full spring work and damping effect regardless of load speed.

- Overload-safe: Designed to "block," preventing damage and exceeding admissible stresses.

- Temperature-independence: Consistent characteristic curve from -20°C to +60°C, unaffected by temperature fluctuations.

- Maintenance-free: Generally does not require relubrication; using other lubricants may cause failure.

- Flexible arrangement: Parallel for higher forces, serial for more spring travel.

- Custom designs: Tailored solutions for specific applications beyond standard offerings.

Learn more about: The History of Ringfeder Friction Springs

Product Specifications of Friction Springs

| Friction Springs Catalogue | Friction Springs Installation Instruction |

| | |

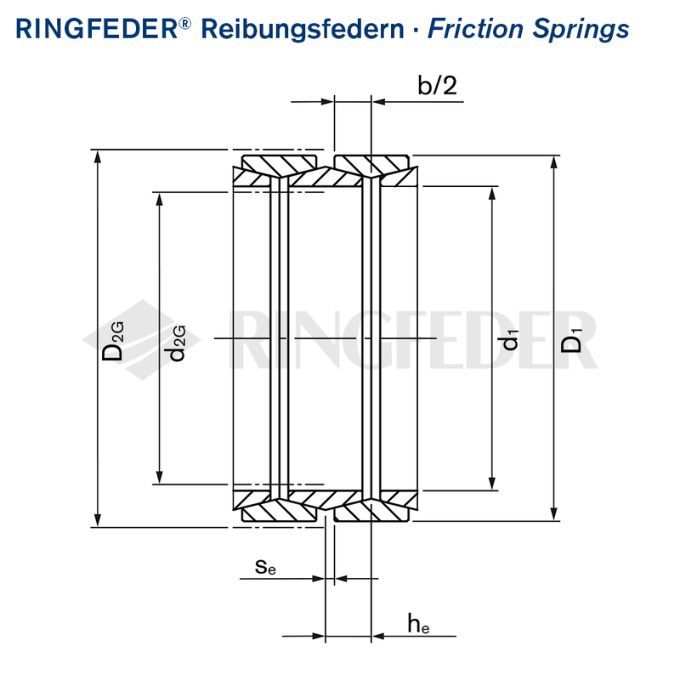

| Type | Diagram | Dimensions | Guide | Gwe | ||||||

| F | Se | We | he | D1 | d1 | b/2 | D2G | d2G | ||

| kN | mm | Joule | mm | mm | mm | mm | mm | mm | kg | |

| 1800 | 5 | 0,4 | 1,0 | 2,2 | 18,1 | 14,4 | 1,8 | 18,7 | 13,9 | 0,002 |

| 2500 | 9 | 0,6 | 2,7 | 3,1 | 25,0 | 20,8 | 2,5 | 25,9 | 20,1 | 0,004 |

| 3200 | 14 | 0,8 | 5,6 | 4,0 | 32,0 | 27,0 | 3,2 | 33,1 | 26,1 | 0,007 |

| 3800 | 20 | 0,9 | 9,0 | 4,7 | 38,0 | 31,7 | 3,8 | 39,3 | 30,6 | 0,012 |

| 4200 | 26 | 1,0 | 13,0 | 5,2 | 42,2 | 34,6 | 4,2 | 43,6 | 33,4 | 0,018 |

| 4800 | 34 | 1,1 | 18,7 | 5,9 | 48,2 | 39,4 | 4,8 | 49,8 | 38,1 | 0,026 |

| 5500 | 40 | 1,3 | 26,0 | 6,8 | 55,0 | 46,0 | 5,5 | 56,7 | 44,5 | 0,035 |

| 6300 | 54 | 1,4 | 37,8 | 7,7 | 63,0 | 51,9 | 6,3 | 64,9 | 50,3 | 0,056 |

| 7000 | 65 | 1,6 | 52,0 | 8,6 | 70,0 | 58,2 | 7,0 | 72,1 | 56,4 | 0,074 |

| 8000 | 83 | 1,8 | 75,0 | 9,8 | 80,0 | 67,0 | 8,0 | 83,0 | 64,0 | 0,105 |

| 9000 | 100 | 2,0 | 100,0 | 11,0 | 90,0 | 75,5 | 9,0 | 93,0 | 73,0 | 0,145 |

| 10000 | 125 | 2,2 | 138,0 | 12,2 | 100,0 | 84,0 | 10,0 | 103,0 | 81,0 | 0,203 |

| 12400 | 200 | 2,6 | 260,0 | 15,0 | 124,0 | 102,0 | 12,4 | 128,0 | 98,0 | 0,408 |

| 13000 | 160 | 2,6 | 208,0 | 15,0 | 130,0 | 111,5 | 12,4 | 134,0 | 108,0 | 0,376 |

| 14000 | 250 | 3,0 | 375,0 | 17,0 | 140,0 | 116,0 | 14,0 | 144,0 | 112,0 | 0,568 |

| 16600* | 350 | 3,7 | 648,0 | 20,0 | 166,0 | 134,0 | 16,0 | 170,0 | 130,0 | 0,869 |

| 19600 | 600 | 4,4 | 1.320,0 | 23,4 | 194,0 | 155,0 | 19,0 | 199,0 | 150,0 | 1,676 |

| 20000 | 510 | 3,9 | 995,0 | 22,4 | 198,0 | 162,0 | 18,5 | 203,0 | 157,0 | 1,570 |

| 22000 | 720 | 4,4 | 1.584,0 | 26,4 | 220,0 | 174,0 | 22,0 | 225,0 | 169,0 | 2,573 |

| 26200 | 860 | 4,8 | 2.064,0 | 25,8 | 262,0 | 208,0 | 21,0 | 268,0 | 202,0 | 3,415 |

| 30000 | 1000 | 5,8 | 2.900,0 | 35,8 | 300,0 | 250,0 | 30,0 | 306,0 | 245,0 | 5,510 |

| 32000 | 1200 | 6,2 | 3.720,0 | 38,2 | 320,0 | 263,0 | 32,0 | 326,0 | 258,0 | 7,060 |

| 35000 | 1400 | 6,6 | 4.620,0 | 41,6 | 350,0 | 288,0 | 35,0 | 356,0 | 283,0 | 9,180 |

| 40000 | 1800 | 7,6 | 6.840,0 | 47,6 | 400,0 | 330,0 | 40,0 | 407,0 | 324,0 | 13,560 |

Why Choose Ringfeder Friction Springs?

RINGFEDER® Friction Springs offer superior advantages over conventional damping solutions, including high spring work at low weight and volume, and high damping capability. They provide consistent performance independent of load speed and are overload-safe in block position. The springs are temperature-independent, maintenance-free, and can be arranged in parallel or series for specific applications.

In addition to standalone spring columns, RINGFEDER® Friction Springs come in complete buffer versions tailored to specific applications and customer needs. These springs are available in various shapes and sizes to suit diverse industries such as mechanical engineering, raw material extraction, processing, and the aviation and aerospace sectors. Common designs include push-pull units that serve as effective vibration dampers or absorbers, and slipping clutches that provide reliable overload protection.

Dai Hong Phat Corp specializes in the supply of genuine Ringfeder Friction Springs throughout Vietnam

Dai Hong Phat Corp is the official importer and distributor of 100% genuine coupling products from the Ringfeder brand across Vietnam and Southeast Asia.

With over 15 years of trusted service, Dai Hong Phat Corp ensures that customers receive high-quality and authentic Friction Springs at the best prices available on the market.

---------------------------------------------------------------------------------------

Contact Dai Hong Phat Corp today to learn more!!

Website: https://ringfeder.com.vn/ - https://daihongphat.asia/

Hotline: 0906 955 057 | Zalo: +84906 955 057

Email: info@dhp-corp.com.vn

Facebook Ringfeder Vietnam: https://www.facebook.com/ringfedervietnam/

Facebook Dai Hong Phat Corp: https://www.facebook.com/khopnoitrucdaihongphat

Featured Products

Instagram

Instagram