RINGFEDER® Friction Springs for Block Band Saws in the Woodworking Industry

- Written by: info@dhp-corp.com.vn on

- Friction Springs

- - 0 Comments

Besides the steel industry with its harsh environment and high temperatures, the woodworking industry is another industry that benefits from RINGFEDER® friction springs.

Systems in the woodworking industry – especially industrial wood sawing machines – require emergency stop solutions that can effectively absorb energy, protect equipment and structures, and ensure operational safety. Let's explore Friction Springs for Block Band Saws in the woodworking industry in the article below.

1. Specific Application: Emergency Stop System for Band Saws

This is a wood saw with a horizontal saw blade guide, used to saw wood vertically.

The saw is fed by hoppers, which clamp and control the logs to be processed.

System used:

- Esterer EWD EW2 model clamp

- Driven by 24 mm diameter steel cable

- Maximum full load weight: 16 tons

- Clamp working speed: 200 m/min (≈ 3.33 m/s)

If the cable breaks suddenly, an emergency stop system is required to absorb the unbraked impact force of the trolley or any resulting forces and energy, thereby preventing system damage. This needs to be done using two shock absorbers for each side of the clamp.

2. Calculation of the design solution before using Friction Springs for Block Band Saws

With the given data, the energy W to be absorbed is calculated to be around 90.000 Joules. Divided over 2 buffers, this results in a rounded figure of 44.400 J per buffer.

As not all the boundary conditions had been fully clarified at the start of the project planning, a double spring in a parallel arrangement was initially considered as a possible solution. It consisted of:

- Standard 16600 type (56 elements)

- Standard 12400 type (80 elements)

The system used standard RINGFEDER® F-S1 grease, as there were no special requirements regarding ambient temperature.

Achieved parameters:

- Preload: FV = 53 kN

- Maximum acting force: FB = 490 kN

- Spring stroke: sB = 164 mm

- Installation length: ~1270 mm

However, this design is no longer suitable as operating requirements have expanded.

Learn more about: Specifications of Ringfeder Industrial Buffers

Image 1: Force-displacement diagram

Image 1: Force-displacement diagram

3. Optimal Solution with Friction Springs for Block Band Saws

This proposed solution had to be abandoned due to new requirements:

- Instead of just one wagon, it should also be possible to stop two wagons attached to each other if necessary.

- Each damper must be capable of absorbing 90,000 Joules

- Additionally, the installation length was limited to 620 mm for space reasons.

To meet these conditions, the final solution was to combine three types of friction springs, including:

- Special type 24201 with 20 elements

- Standard type 1960 with 24 elements

- Standard type 14000 with 34 elements

Operating parameters for each damper:

- FV = 160 kN

- FB = 1267 kN

- Stroke sB = 63 mm

> Although the result did not meet the initial maximum overall length requirement of 620mm (actually 690mm), the design solution using Friction Springs for Block Band Saws was adopted and successfully implemented in practice.

Image 2: RINGFEDER® buffers in the wood industry

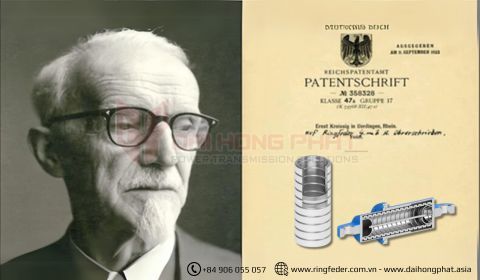

Learn more: The history of Ringfeder Friction Springs

4. Technical Value of Friction Springs for Block Band Saws

In this application, the dampers act as a double layer of protection and prevent damage to the railcar and building structure if the steel cable breaks.

Image 3: Side view of emergency stop buffer

With the enormous volume of moving material and the harsh conditions in woodworking, Ringfeder friction springs are the right solution. Friction springs can be used in both wood saws or to protect clamps from overload.

👉 Contact Ringfeder Vietnam for advice on the friction spring solution that best suits your system's specific technical requirements.

---------------------------------------------------------------------------------------

Contact Dai Hong Phat Corp today to learn more!!

Website: https://ringfeder.com.vn/ - https://daihongphat.asia/

Hotline: 0906 955 057 | Zalo: +84906 955 057

Email: info@dhp-corp.com.vn

Facebook Ringfeder Vietnam: https://www.facebook.com/ringfedervietnam/

Facebook Dai Hong Phat Corp: https://www.facebook.com/khopnoitrucdaihongphat

Instagram

Instagram

Write a comment