Locking Assemblies for Agricultural Shredders – Optimizing Performance for Sustainable Farming

- Written by: info@dhp-corp.com.vn on

- Locking Assemblies

- - 0 Comments

With the increasing demand for sustainable farming and pollution control, scrap shredders are becoming increasingly popular among farmers. However, because the rotating shaft operates at high speed and is directly attached to the shredding blades, shaft slippage can cause the blades to not receive enough force, reducing shredding efficiency.

Please refer to the article below to discover Ringfeder's optimal solution, which ensures stable power transmission and improves the operational efficiency of the shredder.

1. Causes of shaft slippage

In many traditional designs, the connection between the shaft and pulley often uses a keyway. While common and easy to install, this method has several limitations:

- The transmitted force is concentrated at the keyway, easily causing wear and deformation.

- The torque transmission capability is limited, especially in heavy-duty applications.

- After a period of operation, clearance develops, making the shaft prone to slippage.

- These limitations directly affect the working efficiency and durability of the grinding machine.

2. Locking Assemblies for Agricultural Shredders – The Optimal Solution from Ringfeder

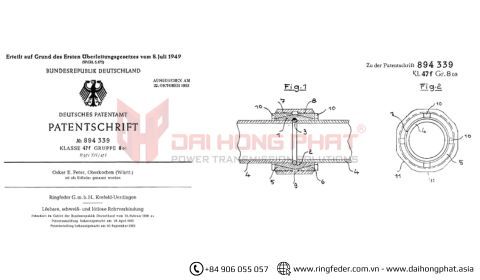

In this application, a completely gapless connection is paramount. The RINGFEDER® friction-based shaft-hub locking system, manufactured to the highest quality standards, perfectly meets this requirement.

The keyless locking assemblies is installed between the pulley and the motor/rotor shaft. When the clamping screws are tightened:

- The inner and outer rings press tightly against the contact surface of the shaft and hub.

- This creates a secure, completely slip-free friction-based connection.

This solution not only allows for reliable transmission of high torque but also withstands axial, radial, and bending loads during operation.

Once again, RINGFEDER POWER TRANSMISSION has successfully solved the customer's application problem, helping the mill manufacturer improve operational reliability and completely satisfy the user.

Learn more about: Ringfeder Locking devices RfN

3. Locking Assemblies for Agricultural Shredders – Superior Reliability Over Traditional Key Connections

Keyway shaft connections are a traditional method, but they are increasingly revealing limitations in heavy-duty applications such as scrap mills:

- Stress concentration at a single contact point

- Prone to wear and clearance

- Limited torque transmission

In contrast, Ringfeder locking assemblies utilize a pair of double conical retaining rings. When tightened, these rings expand radially, creating a tight compression fit between the shaft and hub.

Thanks to the 360° even stress distribution, the locking assembly:

- Eliminates stress concentration

- Reduces wear and maintenance costs

- Provides a highly reliable connection and longer service life

4. Locking Assemblies for Agricultural Shredders - One Solution – Many Applications

Not only for scrap metal shredders, RINGFEDER® locking systems are widely used for:

- Gears, wheels, sprockets

- Cam plates, belt plates, couplings

- Flanges, shafts and wheel axles

With a wide range of standard sizes and custom design options, RINGFEDER® flexibly meets all industrial drive requirements.

Learn more blogs: Application of a Locking Assembly in a Ball Mill for Cement Production

5. Dai Hong Phat Corp – Authorized Distributor of Ringfeder Germany

Locking assemblies play a key role in improving the performance and reliability of agricultural shredders by eliminating shaft slippage and ensuring stable operation. Choosing the right locking solution helps maximize efficiency and supports sustainable farming practices.

As the authorized distributor of Ringfeder Germany, Dai Hong Phat Corp provides genuine locking assembly solutions and professional technical support, helping customers optimize shredder performance and ensure long-term operational reliability.

---------------------------------------------------------------------------------------

Contact Dai Hong Phat Corp today to learn more!!

Website: https://ringfeder.com.vn/ - https://daihongphat.asia/

Hotline: 0906 955 057 | Zalo: +84906 955 057

Email: info@dhp-corp.com.vn

Facebook Ringfeder Vietnam: https://www.facebook.com/ringfedervietnam/

Facebook Dai Hong Phat Corp: https://www.facebook.com/khopnoitrucdaihongphat

Instagram

Instagram

Write a comment